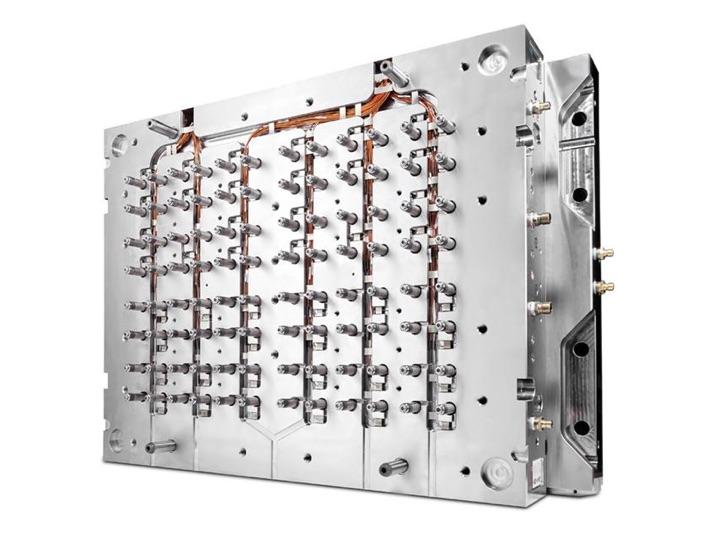

Optimize Efficiency with Clean, MainTained Hot Runner Systems

A well-maintained hot runner system is key to consistent, high-quality output and reduced downtime. Regular hot runner cleaning and maintenance prevent material buildup, eliminate contamination, and improve flow precision—ultimately reducing waste and extending your system’s lifespan. At Polymer Cleaning Technology, we specialize in thorough cleaning services that keep your hot runner systems performing at peak efficiency, saving you time and operational costs while ensuring flawless product quality with every cycle. Invest in maintenance now to avoid costly repairs and keep production on schedule.

The Polymer Cleaning Process

Using the latest cleaning technology our skilled technicians can remove any grade of resin from any manifold regardless of the flow path geometry.

100% Safe

Hot Runner Manifold Cleaning by PCT will not damage/distort the manifold, or alter the surface finish.

Quick & Easy

We’ll clean your Hot Runner Manifold on your schedule. Most jobs are processed and returned within 24 hours, but same-day service is also available.

Thorough & Detailed

Complete removal of resin from the flow channels including all burned and degraded material. Ideal for removing metal from flow channels.

Specially Adapted

Special adaptation to work on high-temperature resins like ULTEM and LIQUID CRYSTAL. Easily cleans manifolds processing nylons up to 40% glass filled.

Same Day SERVICE Available

Hot Runner Refurbishment SERVICES

HUSKY, Männer/MHT, MoldMasters, Otto Hofstetter, Kortec, Sipa, Sacmi, Nissei, Milacron, Yudo + more!

Hot Runner Manifold Cleaning | HOT RUNNER CLEANING | Hot Runner System Repair | Hot Runner Refurbishment Services | Hot Runner Nozzle Repair | Cost-Effective Hot Runner Refurbishment | Hot Runner Preventive Maintenance | Hot Runner Component Rebuild | NOZZLE HEATER REPAIR | Hot Half Refurbishment | Hot Runner upgrades | Hot Runner Part REPAIR

LEAKING HOT HALVES

HOT HALF PM PROGRAMS

HOT RUNNER UPGRADES

Husky Hot Runner Repair Services | Mold-Masters Repair Services | Yudo Repair Services | Manner Repair Services | MHT Repair Services

Mold-Masters Repairs

Mold-Masters Hot Runners are one of the most common systems in use today.

These systems are unique in that the nozzle heater is integral to the housing rather than removable. This design feature offers processing advantages, but can also become an problem in the event

of a leak. Not only are replacement nozzles expensive, but lead time is almost always excessive for new Mold-Masters nozzle components.

Polymer Cleaning Technology has developed proprietary methods to repair and rebuild Mold-Masters nozzles, as well as laser welding broken power leads.

All repairs quoted for completion within 2-3 days.

Send us a Message

Solutions for ALL Hot Runner Injection Molding Systems