Mold Masters Repairs Made Easy

Mold-Masters Repairs, Mold-Masters Refurbishment, Hot Runner Repairs, Hot Runner Cleaning, Hot Runner Manifold Cleaning, Hot Runner Manifold Refurbishment

Mold-Masters Hot Runners are one of the most common systems in use today.

These systems are unique in that the nozzle heater is integral to the housing rather than removable. This design feature offers processing advantages, but can also become an problem in the event of a leak. Not only are replacement nozzles expensive, but lead time is almost always excessive for new Mold-Masters nozzle components.

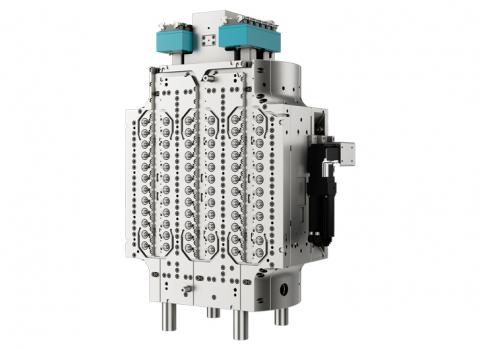

Mold-Masters Manifold Cleaning performed by Polymer Cleaning Technology

Hot Runner Repairs & Hot Runner Cleanings for ALL models at a fraction of the cost utilizing PCT’s proprietary methods. Endless part styles made-to-order with turnaround times up to 10x faster than ordering new!

Nozzle & Power Lead Repairs

Hot Runner Nozzle Repairs, Mold-Masters Nozzle Repairs, Power Lead Repair, Hot Runner Nozzle Repair, Hot Runner Repair

Polymer Cleaning Technology has developed proprietary methods to repair + rebuild Mold Masters nozzles, as well as laser welding broken power leads.

Repairing and rebuilding hot runner nozzles, along with laser welding broken power leads, offers a cost-effective and timely alternative to purchasing new OEM parts. By restoring these components to optimal functionality, manufacturers can significantly reduce expenses while minimizing downtime, ensuring a faster return to production.

All repairs quoted for completion within 2-3 days.